You can use a cutter for metal and hammer to unscrew the rusty nut or screw. During the hit, the cutter is set a bit oblique, so that the forces from the impacts will unscrew the nut. We also set the cutter like this, In order not to touch the nuts with the entire length of the blade but only with the corner. We put the cutter in various places around the perimeter. First we hit slightly, To loosen the threaded connection. When it goes, we hit more strongly.

You can use a cutter for metal and hammer to unscrew the rusty nut or screw. During the hit, the cutter is set a bit oblique, so that the forces from the impacts will unscrew the nut. We also set the cutter like this, In order not to touch the nuts with the entire length of the blade but only with the corner. We put the cutter in various places around the perimeter. First we hit slightly, To loosen the threaded connection. When it goes, we hit more strongly.

Suspending on discs

Perfect attachment on thin plates can be made with a screw with a conical and short longitudinally cut tube. We cut the tube crossly, to create four parting walls. When we cut the cap on the pipe inserted into the tube, this will cause a movement movement, and thus parting the walls of the tube and its anchoring in the plate. Such attachment, Very cheap can be made of aluminum or brass tube.

Hammering

Picking up posts and Żerdi into the ground is much more convenient and faster than digging them. In this case, the end of the forage should be harassed spicy and impregnated. When the bars and Żerds are long, They can be driven from the bridge or a ladder set next to it using a heavy, generally 5 kg with a hammer. Instead of using the bridge, it is much more convenient and faster on the post to slide a steel cover with two wedges, which is hit with a hammer. In the case of round bars, two wedges may not be enough.

Enda

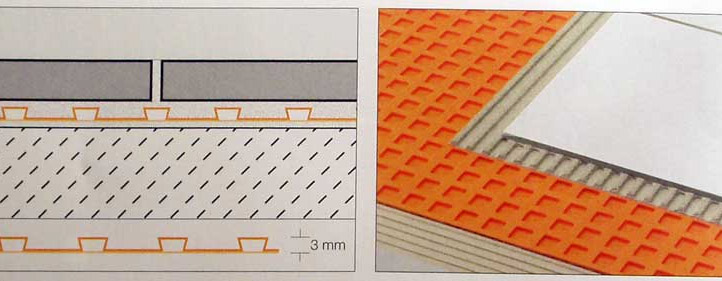

Ceramic tiles on terraces or balconies are exposed to rapid destruction. The reason is very high stresses resulting from the temperature difference. Let's remember, that in summer such a floor is heating even to temperature +60 stairs c, and in winter it cools down to a temperature even -30 stairs c. Protection against stress in the underlyput layer may be a ditra mat compensating for these stresses. We glue it to the ground with typical adhesive mortar and, in turn, with the same mortar, stick ceramic tiles.

Ceramic tiles on terraces or balconies are exposed to rapid destruction. The reason is very high stresses resulting from the temperature difference. Let's remember, that in summer such a floor is heating even to temperature +60 stairs c, and in winter it cools down to a temperature even -30 stairs c. Protection against stress in the underlyput layer may be a ditra mat compensating for these stresses. We glue it to the ground with typical adhesive mortar and, in turn, with the same mortar, stick ceramic tiles.

Pruning the foil

In many cases, the purchased foil or paper is too wide to our needs. So it must be cut along the length. You can cut the whole roll after developing, But it is too laborious. It is better to cut the whole roll to the right length. This can be done with a background saw or other with the smallest as possible teeth. So that the saw does not block during cutting, The roll should be rotated evenly around the longitudinal axis throughout the cut and periodically immerse the saw in water with a lot of soap.

In many cases, the purchased foil or paper is too wide to our needs. So it must be cut along the length. You can cut the whole roll after developing, But it is too laborious. It is better to cut the whole roll to the right length. This can be done with a background saw or other with the smallest as possible teeth. So that the saw does not block during cutting, The roll should be rotated evenly around the longitudinal axis throughout the cut and periodically immerse the saw in water with a lot of soap.

Staves

Floor staves can be glued to the ground in different system to form a variety of patterns. Most often arranged in the so -called. herringbone, But you can also in a double herringbone. The layout or so -called. brick, in which the staves are laid with parallel belts with a half -length shift. The double system in the brick and the so -called. deck. In the latter. This last layout, however, resembles a floor from panels. So it is rarely used.

Dybel four -sided

The latest construction of Fischer, specializing in the attachment technique is the SX dowel, in which the spread in the hole when screwing the screw is implemented through four expansion walls. Thanks to this, a lot of attachment is obtained in both full and crevice materials (np. pustakach). Typical wood screws and chipboard screws can be used for dowels characterized by a deep thread sculpture. These dowels are intended for wood, construction ceramics, concrete, light concrete, etc..

The latest construction of Fischer, specializing in the attachment technique is the SX dowel, in which the spread in the hole when screwing the screw is implemented through four expansion walls. Thanks to this, a lot of attachment is obtained in both full and crevice materials (np. pustakach). Typical wood screws and chipboard screws can be used for dowels characterized by a deep thread sculpture. These dowels are intended for wood, construction ceramics, concrete, light concrete, etc..

Key designation

In a large kennel break, it's hard to find the right one, especially then, when they are very similar to each other. And this is the case with Yale keys. It is easier to distinguish them, When we slide colorful overlays available in stores on their heads. However, in the prevailing darkness we will choose the right key, when we make cuts of different shapes or in different quantities on one edge. Dragging with your finger will allow you to distinguish the right one without having to carefully look at the shape of the cut -out on the edge.

In a large kennel break, it's hard to find the right one, especially then, when they are very similar to each other. And this is the case with Yale keys. It is easier to distinguish them, When we slide colorful overlays available in stores on their heads. However, in the prevailing darkness we will choose the right key, when we make cuts of different shapes or in different quantities on one edge. Dragging with your finger will allow you to distinguish the right one without having to carefully look at the shape of the cut -out on the edge.

Installation of the HEPWORTH system

The system of pipes and fittings from polybutylene is extremely useful for independent installers, called hep2O. Installation consists of inserting the end of the pipe into a special fitting socket. Sealing in it ensures full tightness and long life thanks to the use of special seals with high durability and elastic pressure rings. The system consists of pipes of various external diameters and a full range of fittings and connectors also, which are used to connect with other installations.

The system of pipes and fittings from polybutylene is extremely useful for independent installers, called hep2O. Installation consists of inserting the end of the pipe into a special fitting socket. Sealing in it ensures full tightness and long life thanks to the use of special seals with high durability and elastic pressure rings. The system consists of pipes of various external diameters and a full range of fittings and connectors also, which are used to connect with other installations.