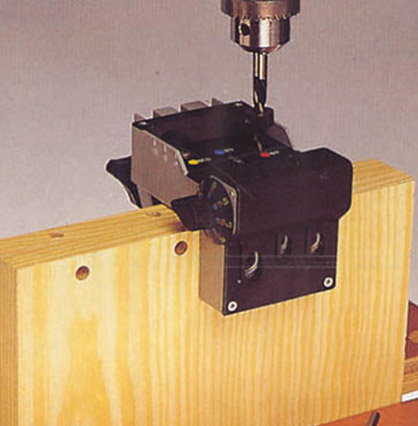

Stick joints on the foreheads of wooden patches require two holes in strictly defined places and perpendicular. This can be provided by attaching a drill in a horizontal stand and laying a patch on a horizontal table compact with several boards. We put the drilled patch sideways to the side resistance from a long strip. After drilling the first opening, we rotate the patch 180 degrees and we drill a second hole. To get a perpendicular hole to the forehead, we need to set the drill in the stand very accurately opposite the horizontal table.

Stick joints on the foreheads of wooden patches require two holes in strictly defined places and perpendicular. This can be provided by attaching a drill in a horizontal stand and laying a patch on a horizontal table compact with several boards. We put the drilled patch sideways to the side resistance from a long strip. After drilling the first opening, we rotate the patch 180 degrees and we drill a second hole. To get a perpendicular hole to the forehead, we need to set the drill in the stand very accurately opposite the horizontal table.

Table

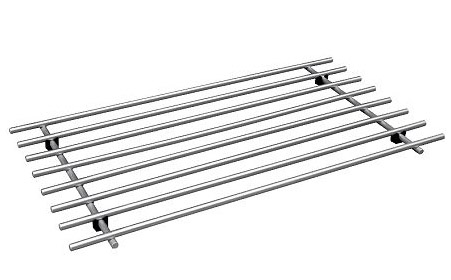

The practical device in the kitchen is a table for a table for hot dishes. It can be glued from thin slats or use the appropriate size steel grate offered for garden grills. The metal grate can be supplied with higher legs, so that you can place small candles for heating dishes in the dishes. You can also attach the grate on a special base compacted from boards of wood of precious species. In any case, it is worth sticking four short cork legs on the bottom.

The practical device in the kitchen is a table for a table for hot dishes. It can be glued from thin slats or use the appropriate size steel grate offered for garden grills. The metal grate can be supplied with higher legs, so that you can place small candles for heating dishes in the dishes. You can also attach the grate on a special base compacted from boards of wood of precious species. In any case, it is worth sticking four short cork legs on the bottom.

Magnetized screwdriver

Very strong magnetization of screwdriver blades is worth recommending in a home workshop. This magnetization should be so strong enough, so that the screw attached to the blade does not fall under its own weight. Then it will be possible to transfer it to the screwdriver in place, in which he will be screwed in, without having to hold with the other hand. This way you will only be able to screw in steel screws. Those of colored metals and the larger length and too heavy will be kept.

Piła for route

The Pilan Pilament should be adapted to designate perpendicular lines on the cut elements. If you want to cut a perpendicular board, you won't have to look for a carpentry angle. Just use a saw for ruting, which is already at hand. In order for the saw to constitute an angle, to form a right angle with the upper edge of the blade. After such a handle to the side of the board, We draw a line with a perpendicular pencil applied to the upper edge of the blade.

Correct threading

Proper threading of both internal and external threads should be followed by. After placing the threader in the hole or sliding on the mandrel, we make one full rotation of the tool in the direction consistent with the movement of the clockwise, and then turn in the opposite direction Fr. 1/4 rotation. And thus until the total incision of the thread. These movements guarantee the cutting of short chips by blades, and thus obtaining a good quality thread.

Proper threading of both internal and external threads should be followed by. After placing the threader in the hole or sliding on the mandrel, we make one full rotation of the tool in the direction consistent with the movement of the clockwise, and then turn in the opposite direction Fr. 1/4 rotation. And thus until the total incision of the thread. These movements guarantee the cutting of short chips by blades, and thus obtaining a good quality thread.

Horizontal setting

Such household appliances as washing machines, refrigerator, The freezer or dishwasher requires accurate setting and leveling. They will be poorly leveled the source of noise during work, and worse, excessive vibrations of mechanisms will cause faster wear of the parts. We can use a deep tableware plate for leveling, into which we pour colored water. Observing the water mirror relative to the edge of the plate, we can determine very carefully, which leg under the device should be adjusted.

Such household appliances as washing machines, refrigerator, The freezer or dishwasher requires accurate setting and leveling. They will be poorly leveled the source of noise during work, and worse, excessive vibrations of mechanisms will cause faster wear of the parts. We can use a deep tableware plate for leveling, into which we pour colored water. Observing the water mirror relative to the edge of the plate, we can determine very carefully, which leg under the device should be adjusted.