Cement concrete surfaces are most often made by laying concrete and forming plates from it at the destination. The sizes of the plates are limited; The principle applies, that the ratio of the thickness of the concrete plate to its length should be approximately 1 : 10. This is due to the mechanical properties of concrete, which in plates of significant size and small thickness is easily cracking and breaks. Therefore, making concrete laid on the spot of exceeding dimensions 1 m requires a proportional increase in their thickness, which in garden conditions is not justified by the required strength or other reasons. Therefore, side panels are not usually used 1 m and the thickness of the exceeding 10 cm. You should also add here, that in the event of damage, np. plate cracks, Replacing them always causes a lot of trouble.

Cement concrete surfaces are most often made by laying concrete and forming plates from it at the destination. The sizes of the plates are limited; The principle applies, that the ratio of the thickness of the concrete plate to its length should be approximately 1 : 10. This is due to the mechanical properties of concrete, which in plates of significant size and small thickness is easily cracking and breaks. Therefore, making concrete laid on the spot of exceeding dimensions 1 m requires a proportional increase in their thickness, which in garden conditions is not justified by the required strength or other reasons. Therefore, side panels are not usually used 1 m and the thickness of the exceeding 10 cm. You should also add here, that in the event of damage, np. plate cracks, Replacing them always causes a lot of trouble.

Making the surface from concrete panels laid at the destination is quite troublesome due to the need to prepare or transport concrete. Activities related to the construction of these surfaces also require a significant workload.

For these reasons, this method of making concrete slabs cannot be recommended for use on a larger scale.

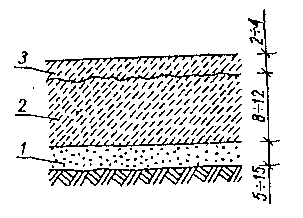

The plates are made of gravel or oxidal concrete B7.5 or B15. Concrete can be laid in two layers, the lower layer of the thickness of approx 2/3 CDs can be made of lower strength concrete. The thicker aggregate can be used for this layer. Concrete slabs should be made on at least a few centimeters bed of gravel or coarse -grained sand spread on a well -stable ground.

Concrete surface: 1 - gravel or coarse sand, 2 - Beton Klasy B7, 5, 8 - Beton Klasy B15.

Concrete surface: 1 - gravel or coarse sand, 2 - Beton Klasy B7, 5, 8 - Beton Klasy B15.