The advantage of making concrete plates laid at the destination is the possibility of a large variety of sizes and the shape of the plates, so you can get interesting artistic effects. The designed shape is suitable for plates by setting the boards, wooden slats, metal or other materials separating the plates made.

A very big advantage of the discussed method of making concrete slabs is also the possibility of very different shaping their surfaces and giving them different structural and decorative features. The surfaces of the plates can be smoothed, blurred on spicy and different ways invoiced.

Invoicing is the surface of the appropriate external appearance. The most commonly used methods include crush of various types of aggregate and different sizes into the surface of fresh leveled concrete and leaching (exposure) specially selected aggregate, from which the top layer of the concrete plate is made. A aggregate used for pressing into the surface of fresh concrete can be of various origins (gravel or crushed) and different colors.

If possible, harassment of hard -abrasive hard rocks should be used. Aggregates with small, grains are scattered on the surface of the concrete, However, aggregate with larger grains, such as. A few centimeters diameter flat pebbles of river origin, it is usually manually arranged. This enables careful selection of their size, proportion, color etc.. The concrete surface before laying such aggregate should be slightly below the edge of the mold. Each aggregate grain should be so immersed in a concrete mixture, so that it can not easily crumble.

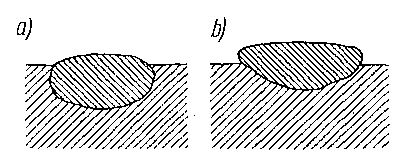

Dipping of stones in the surface layer of concrete: a) appropriate, b) improper.

Dipping of stones in the surface layer of concrete: a) appropriate, b) improper.

Concrete slabs with aggregate surfaces always harmonize well with various elements of the garden, and above all with plants. Therefore, such plates are very valued and increasingly used in the gardens.