Stone cubes surfaces, clinker, cobblestones and plates are made similarly to gravel and crushed. The condition for maintaining the smoothness of the surface built of these materials is to prevent them from pressing them into the substrate under the loading load. Pressing it is even easier, The smaller the surface of individual elements forming the surface. The easiest way to ensure the permanent location of the concrete slabs of larger sizes, np. 50 x 50 cm.

Stone cubes, clinker, cobblestones or plates are usually arranged on 5-20 centimeter layer of sand bed with homogeneous grainness.

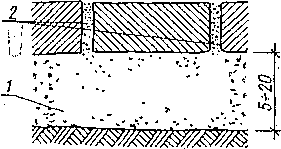

Pedestrian traffic surface made of plates, cubes or clinker 1 - sand or sand with cement (1 : 12), 2 - welds filled with sand or cement mortar.

Pedestrian traffic surface made of plates, cubes or clinker 1 - sand or sand with cement (1 : 12), 2 - welds filled with sand or cement mortar.

Such sand is quite easy, which makes it easier to lay ankles or plates; However, they are not thickened after laying, which prevents surface deformation.

The materials laid on sand bedside do not change their position under the influence of loads, If the surface is used only by pedestrians. If necessary, if you need to increase the strength of such surfaces. The most commonly used cement-sand bedside is used here 10-20 cm. Cement is added to the sand usually in the proportion 1 : 12. In parking lots, where, due to the high load, cement-sand may prove insufficient, A layer of lean concrete thickness is used under the ankle or clinker 10-15 cm, and then these materials are laid on a few centimeters cement-sand beds. The foundation for surfaces heavily loaded especially on impermeable soils is made of a 10-20-centimeter layer of crushed stone. The ankle is laid on this layer after proper compaction, clinker or cobblestone with coarse sand or on cement-lime bedding.

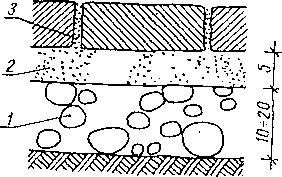

Ankle or clinker surface on the impermeable ground 1 - crushed or gravel, 2 -sand or cement-sand beds, 3 - sand or mortar.

Ankle or clinker surface on the impermeable ground 1 - crushed or gravel, 2 -sand or cement-sand beds, 3 - sand or mortar.