Gravel and crushed surfaces can be thickness 6 – 20 cm, depending on the permeability of the substrate and the expected load. Surfaces on loose and permeable soils may be a small thickness,

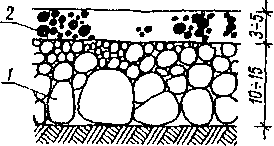

Gravel-plastic surface on a permeable 1 - thick gravel or crushing, 2 - Cliniec,

Gravel-plastic surface on a permeable 1 - thick gravel or crushing, 2 - Cliniec,

However, the impermeable on the ground are usually much thicker.

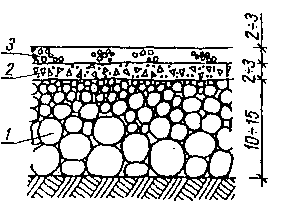

Nawierzchnia żwirowo-tłuczniowa na podłożu nieprzepuszczalnym 1 - thick gravel or crushing, 2 - Cliniec, 3 - sorted gravel

Nawierzchnia żwirowo-tłuczniowa na podłożu nieprzepuszczalnym 1 - thick gravel or crushing, 2 - Cliniec, 3 - sorted gravel

The lower part of the surface acts as a drainage layer in these conditions. In order to drain excess water at the bottom of the excavation under the road (called bearing) You can arrange the forests that allow the water outflow of the accumulating.

Gravel used to build this type of surface should have granted variations within the borders 1-5 mm. This is a condition for mutual clinic of grains, which ensures the durability of the surface profile. Loose larger grains, not related to the surface, they make cooling difficult and contribute to the formation of unevenness. Therefore, for the construction of the surface layer of the surface should not be used in natural or glacial aggregate. Such aggregate has rounded grains and difficult to clamp (cursing) in the surface.

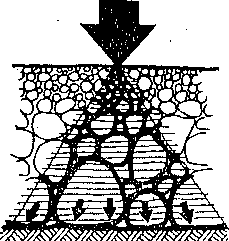

In order to adapt the road to carrying higher loads, its thickness increases, Thanks to this, the loads are transferred through the clinic aggregate grains to a large surface of the substrate.

Moving to the substrate of a concentrated force burdening the crushing surface.

Moving to the substrate of a concentrated force burdening the crushing surface.

This is how the surface deformations are prevented. The rational distribution of forces is obtained by laying the surface from layers of varying grainness, The thickest aggregate is falling apart, or arranges the lowest. Each subsequent layer should have such grain, that the unevenness of the previous layer would be equalized. This is also a condition for the mechanical binding of aggregate grains, mainly thanks to mutual clinic.