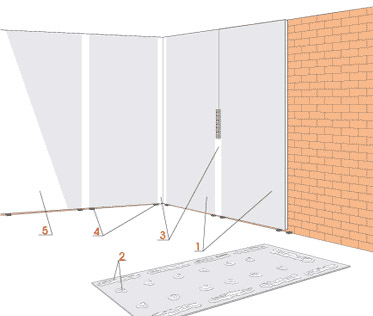

We can finish the surfaces of brick walls with plasterboard, not plastered. The plates glued to the surface create a ready plaster, quality better than traditional, and besides, they eliminate the use of the so -called. wet technologies (plastering), which introduce additional moisture into the rooms. They are glued with gypsum mortar applied with pancakes evenly arranged on the bottom of the plates. Just set up vertically after this disc, Adjust to the neighboring ones and press against the wall. Then we are cooling the contacts of the disc.

We can finish the surfaces of brick walls with plasterboard, not plastered. The plates glued to the surface create a ready plaster, quality better than traditional, and besides, they eliminate the use of the so -called. wet technologies (plastering), which introduce additional moisture into the rooms. They are glued with gypsum mortar applied with pancakes evenly arranged on the bottom of the plates. Just set up vertically after this disc, Adjust to the neighboring ones and press against the wall. Then we are cooling the contacts of the disc.

Ceramics pad

The downwards standing bowls and the bidets were generally settled, well fresh, melted cement mortar and after its hardening it screwed to the ground with anchors. This guaranteed the support of the entire bottom of the bowl on an equal foundation. Better solution, The use of pads in the form of flexible adhesive tapes is guaranteeing proper support. They are glued to the bottom of the ceramics and is attached with anchors with it. It is also good to cut a pad of thicker 2-4 mm polyurethane foam or technical cork.

Water outflow from the washing machine

When making a sewage installation in our house or apartment, we must remember to connect the washing machine or dishwasher to the existing collective installation. Well, the outflow from these devices cannot be located lower with a drain from sanitary facilities, e.g.. sinks or toilet bowl. When it is lower, This can lead to the reversing of impurities and their influence into the washing machine or dishwasher, and thus can cause high pollution of washing or dishes.

Insulating facade plates

In wooden buildings, additional insulation can be glass wool facade boards attached to the outer surface of the wall. These plates are then covered with a siding facade or a facade of boards arranged vertically or horizontally. Depending on the thickness of the plate, you can reduce the heat transfer coefficient U (former K) for walls even to 0,2 W/m2K. Before nailing the facade.

In wooden buildings, additional insulation can be glass wool facade boards attached to the outer surface of the wall. These plates are then covered with a siding facade or a facade of boards arranged vertically or horizontally. Depending on the thickness of the plate, you can reduce the heat transfer coefficient U (former K) for walls even to 0,2 W/m2K. Before nailing the facade.

Cramzyitetone blocks

For thermal insulation, Especially the floors on the ground should be used rectangular blocks made of expanded clay concrete. This material is small clay granules connected by cement mortar. A z kolei keramzyt to, As you know, good insulation material was created by obtaining small granules, closed air pores in the process of firing clay so -called, polandation. Various types of wall blocks with very good thermal insulation are also made of expanded clay.

For thermal insulation, Especially the floors on the ground should be used rectangular blocks made of expanded clay concrete. This material is small clay granules connected by cement mortar. A z kolei keramzyt to, As you know, good insulation material was created by obtaining small granules, closed air pores in the process of firing clay so -called, polandation. Various types of wall blocks with very good thermal insulation are also made of expanded clay.

Cutting the paving stones

For cutting, Or rather, splitting concrete blocks, brick, stones etc.. It is worth making a simple device. Hard steel cutting blades move in it in two side stem, prisoners in a steel base. You have to hit the blade very strongly with a hammer, preferably very heavy weighing around 5 kg. One strong hammer blow, With the proper shape of the cutting edge of the instrument, the cube should be splitting.

For cutting, Or rather, splitting concrete blocks, brick, stones etc.. It is worth making a simple device. Hard steel cutting blades move in it in two side stem, prisoners in a steel base. You have to hit the blade very strongly with a hammer, preferably very heavy weighing around 5 kg. One strong hammer blow, With the proper shape of the cutting edge of the instrument, the cube should be splitting.

Ceramic tile top

We will make a perfect top for standing kitchen cabinets with thick 25 mm of chipboard or glued two with a smaller thickness. Them the top is thicker, the greater its strength and stiffness. We attach ceramic floor or universal tiles to the upper surface of the countertop. Important, to determine the location of the tiles thoroughly with plastic distance crosses. The welds must be equal. We then fill them with a silicone coat of the right color.

We will make a perfect top for standing kitchen cabinets with thick 25 mm of chipboard or glued two with a smaller thickness. Them the top is thicker, the greater its strength and stiffness. We attach ceramic floor or universal tiles to the upper surface of the countertop. Important, to determine the location of the tiles thoroughly with plastic distance crosses. The welds must be equal. We then fill them with a silicone coat of the right color.