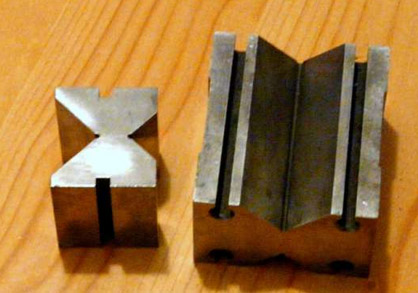

When drilling holes in steel or wooden objects, it is necessary to support them in the prisms, which protect against trading. The prism can be cut from a piece of wooden block. You can also, which is much easier to make it from two halves of a short cylinder cut longitudinally along the axis. Half of the cylinder, just nail with nails to the base from the board or thick plywood. The pile made in this way is especially suitable for fastening rollers with small diameters.

When drilling holes in steel or wooden objects, it is necessary to support them in the prisms, which protect against trading. The prism can be cut from a piece of wooden block. You can also, which is much easier to make it from two halves of a short cylinder cut longitudinally along the axis. Half of the cylinder, just nail with nails to the base from the board or thick plywood. The pile made in this way is especially suitable for fastening rollers with small diameters.

Two -stage glass drilling

That the glass does not crack when drilling the hole, It should be drilled in two stages. First we drill on one side, half the thickness. Then from the other side – Already throughout the thickness. I remind you, that when drilling the glass, we need to set the drill to the lowest possible speed or better drill with a manual drill, lubricating the drill all the time. The drilled glass should be placed on the elastic, but hard ground, e.g.. wood -based plate.

That the glass does not crack when drilling the hole, It should be drilled in two stages. First we drill on one side, half the thickness. Then from the other side – Already throughout the thickness. I remind you, that when drilling the glass, we need to set the drill to the lowest possible speed or better drill with a manual drill, lubricating the drill all the time. The drilled glass should be placed on the elastic, but hard ground, e.g.. wood -based plate.

Tracking of the circle

One of the necessary tools in a well -equipped home workshop is a metal route metal circus. Before round features are made on metal surfaces, and also on hard wood species. You can also measure the dimensions there, where access with a measure is impossible. During use, remember about the periodic warning of both circus legs, Preferably on a regular sheet, one that is used to sharpen carpentry chisels. It must be a flat wheele with very small grains.

One of the necessary tools in a well -equipped home workshop is a metal route metal circus. Before round features are made on metal surfaces, and also on hard wood species. You can also measure the dimensions there, where access with a measure is impossible. During use, remember about the periodic warning of both circus legs, Preferably on a regular sheet, one that is used to sharpen carpentry chisels. It must be a flat wheele with very small grains.

Screwing of the eyelets

Eyelets, In this and hooks for childish swings, we usually screw in wooden beams or posts. We screw it into properly drilled pilot holes, but despite this it requires the use of a lot of force. The torque can be significantly increased by sliding in a thicker rod or tube into the eyelets and by turning such a set both. However, we must be careful, in order not to use too much screwing force, because with very dry wood it threatens with a beam.

Eyelets, In this and hooks for childish swings, we usually screw in wooden beams or posts. We screw it into properly drilled pilot holes, but despite this it requires the use of a lot of force. The torque can be significantly increased by sliding in a thicker rod or tube into the eyelets and by turning such a set both. However, we must be careful, in order not to use too much screwing force, because with very dry wood it threatens with a beam.

Holes in the load -bearing walls

Window or door openings can be successfully forged in masonry partition walls. This is more complicated in the case of load -bearing walls (structural). To make a hole, you must first mount the lintel, e.g.. from steel or reinforced concrete beams. So first on both sides, You should forge furrows and concrete beams in them, e.g.. Steel censers or double -dimensions of the right dimension. The hole under the beams can be carved only after a good concrete.

Window or door openings can be successfully forged in masonry partition walls. This is more complicated in the case of load -bearing walls (structural). To make a hole, you must first mount the lintel, e.g.. from steel or reinforced concrete beams. So first on both sides, You should forge furrows and concrete beams in them, e.g.. Steel censers or double -dimensions of the right dimension. The hole under the beams can be carved only after a good concrete.

Dust tank

To limit the dustiness of the room while drilling holes in the walls, it is worth hanging a small paper envelope from a stiff cardboard under the place of drilling. The dust falling will fall into it, And hence it is easy to remove. The envelope is glued with two short straps of the taper tape. If we stick the envelope just below the hole, This will also protect the wall against dust dirty, and the dust made of bricks or ceramic blocks is particularly dirty.

To limit the dustiness of the room while drilling holes in the walls, it is worth hanging a small paper envelope from a stiff cardboard under the place of drilling. The dust falling will fall into it, And hence it is easy to remove. The envelope is glued with two short straps of the taper tape. If we stick the envelope just below the hole, This will also protect the wall against dust dirty, and the dust made of bricks or ceramic blocks is particularly dirty.

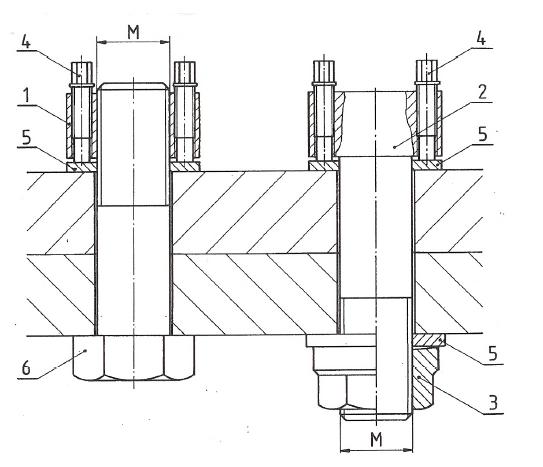

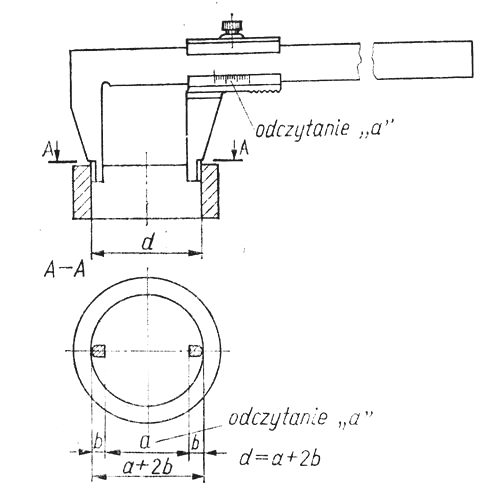

Internal measurement

An ordinary rolled steel measure can also be effectively measured by internal dimensions, e.g.. width of the recess. Enough, that the bent measuring measure will be tightly to the side walls and read the dimension taking into account the error resulting from the radius of the bend. We usually add 1 cm, to get the right dimension. In any case, the measurement will be characterized by speed and generally sufficient accuracy especially for various construction and carpentry works.

An ordinary rolled steel measure can also be effectively measured by internal dimensions, e.g.. width of the recess. Enough, that the bent measuring measure will be tightly to the side walls and read the dimension taking into account the error resulting from the radius of the bend. We usually add 1 cm, to get the right dimension. In any case, the measurement will be characterized by speed and generally sufficient accuracy especially for various construction and carpentry works.

Removing nails

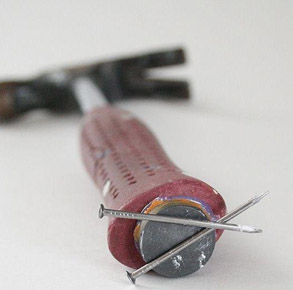

Most small items, such as nuts, pads, bolts, We store the screws and nails in various sizes of boxes or jars. Sometimes it is difficult to take them out of them, Therefore, we most often pour all the contents on the paper. However, you can do it differently. It is enough to paste a small magnet in the hammer of the hammer handle with a two -component glue. Before we take a dozen or so trifles out of the box, We choose the needed, And throw the rest back. The magnet will also facilitate the collection of scattered trinkets.

Most small items, such as nuts, pads, bolts, We store the screws and nails in various sizes of boxes or jars. Sometimes it is difficult to take them out of them, Therefore, we most often pour all the contents on the paper. However, you can do it differently. It is enough to paste a small magnet in the hammer of the hammer handle with a two -component glue. Before we take a dozen or so trifles out of the box, We choose the needed, And throw the rest back. The magnet will also facilitate the collection of scattered trinkets.